Gantry Robot Peening of Aircraft Engine Components

Home / Shot Peening Videos / Gantry Robot Peening of Aircraft Engine Components

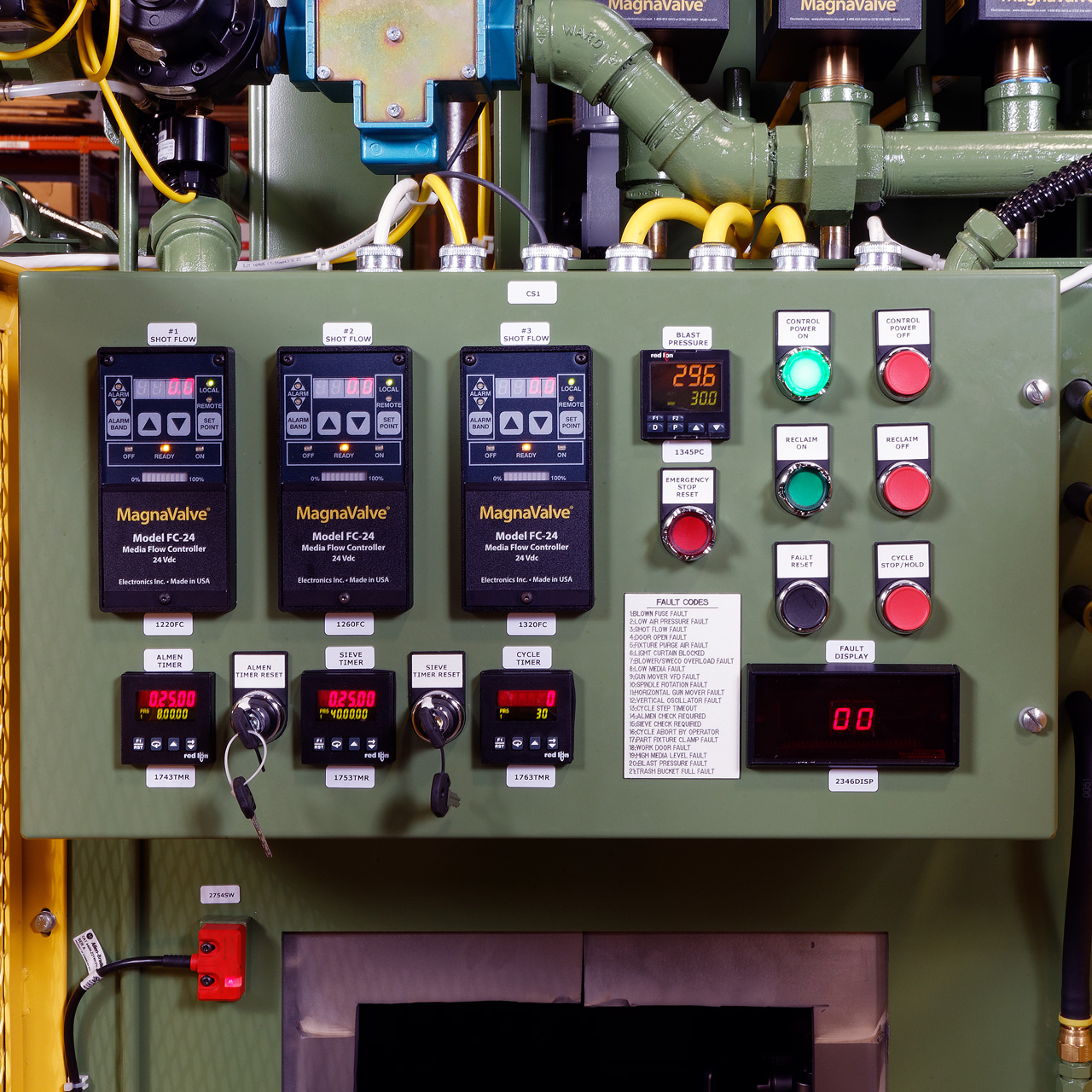

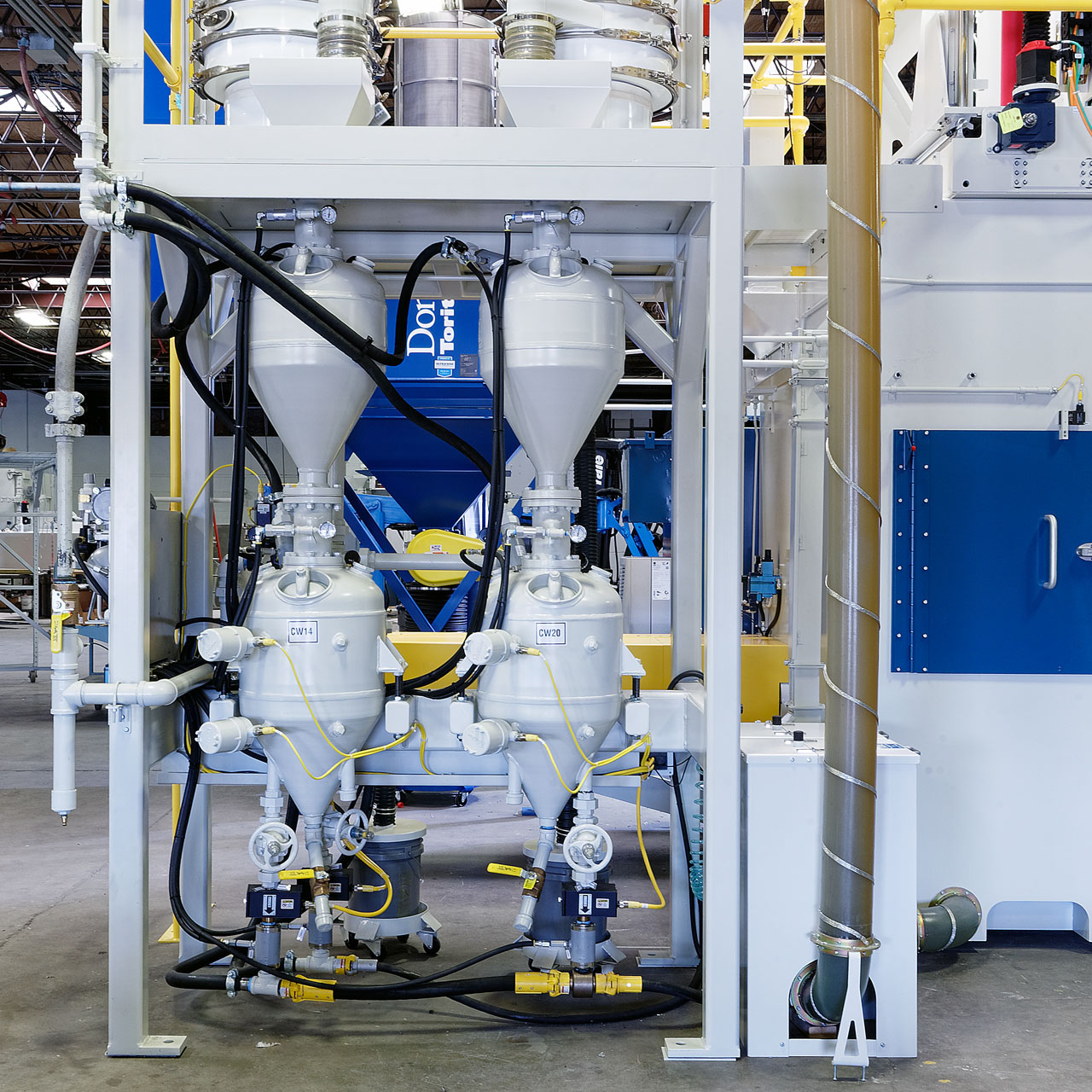

A Gantry Robot is integrated with part manipulation to peen critical surfaces on a variety of aircraft engine components. Venturi nozzles are used to cover large line-of-site surfaces. A rotating lance peens dovetails on fan disks. A 0.090 inch diameter lance is used to peen oil holes on shafts. The machine automatically shifts between three different media sizes. The shaded Almen strip method is used to determine Intensity for small lances.

Related Machines

PRIMS Pro® Process Reporting and Integrated Monitoring System

Advanced, flexible process control for shot peening, grit blasting, and waterjet cleaning.

Read More

Lean Automated Turbine Blade Root Peen

Small and flexible footprint for easy integration into the cell workflow.

Read More

Compact Gantry Robotic Shot Peen with Multiple Media Sizes

Very capable, compact, yet easy-to -perate system for peening aerospace parts.

Read More

Aircraft Engine Shaft Peening

Large scale machine with robot on linear axis peens with six different shot sizes.

Read More