Air filter

Mechanism for cleaning air of contaminants such as water, oil and solid matter.

Alloy

A substance having metallic properties and being composed of two or more chemical elements of which at least one is metal.Almen gauge

An instrument using a dial or digital indicator, a plunger and a platform for mounting an Almen strip. The gauge is used to measure the arc height of a peened Almen strip. Digital gauges provide arc height readings to four decimal places (0.0001″).

Almen strip

Thin strips of spring steel used to quickly gauge the shot peening process. Developed by John Almen at General Motors, these strips are used in conjunction with an Almen gauge to determine the intensity of the shot peen stream.Arc height

A measurement of the amount of deflection or bow in an Almen strip, after it has been shot peened. The measurement is taken at the center of the concave side of the peened Almen strip using an Almen gauge. Readings are normally in thousandths of an inch (0.001″), or in millimeters (mm), while digital gauges can provide readings out to 0.0001″.Blast angle

Angle of a blasting nozzle relative to the surface being blasted with abrasive, shot or waterjet.Blast nozzle

Device through which abrasive or shot is propelled onto a surface during grit blasting or shot peening. The two primary types of blast nozzles are (1) the straight bore nozzle, which has a small opening and a concentration of power in the center of the blast pattern; and (2) the Venturi nozzle, which has a large mouth, tapered mid-section, and a flared opening.

Breakdown rate

The rate at which abrasive or shot particles become too small to be reused after a certain number of impacts (blasting or peening cycles).Cold working

The process of deforming metal plastically beyond its yield strength but below its recrystallization temperature (normally room temperature). Cold working normally sets up residual stresses in the material, and is achieved through stretching, compressing, bending, twisting, cold rolling, cold drawing, and by shot peening.Compressive stress

Force or forces applied toward a common point, for instance a block squeezed in a vise.Coverage

The measurement of surface area which has been shot peened as indicated by the degree of overlapping dimples, expressed as a percentage of a complete overlapping of dimples.Dew point

The temperature at which air becomes saturated with water, that is, when the air is at 100 percent relative humidity. Below this temperature, moisture will condense and produce dew or fog. As air cools, the amount of water vapor it can hold decreases.Embedment

The adherence of particles of blast cleaning abrasive (or broken shot) on a substrate. The particles cannot be removed by brushing or blowing down with compressed air.Fatigue failure

The fracture of a material due to cyclic stresses or loads.Ferrous

A chemical compound or metal alloy that contains primarily iron.

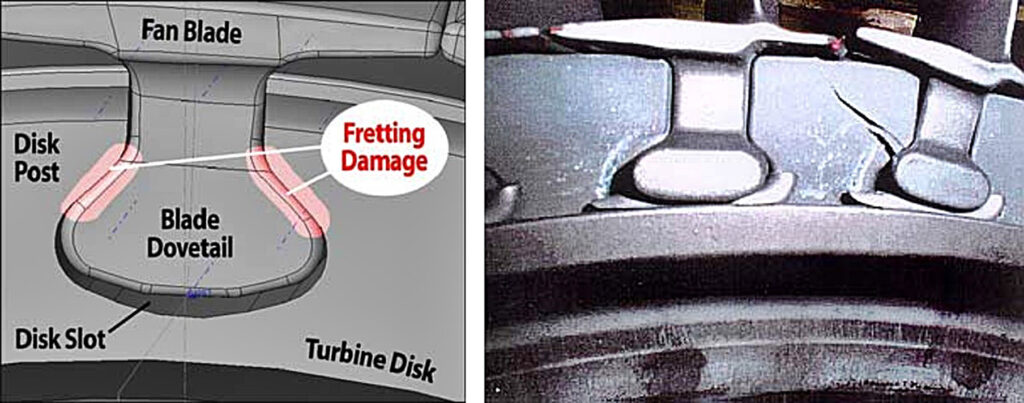

Fretting

A type of wear that occurs between tight-fitting surfaces subjected to cyclic relative motion of extremely small amplitude.

Galling

A condition caused by excessive friction between high spots in a material resulting in localized welding with subsequent spalling.High efficiency particulate air (HEPA) filter

An air filter that removes 99.97 percent of all particles larger than 0.3 microns.

Non-ferrous

A material not containing iron such as non-iron metals, oxides, glass beads and ceramic particles.

Peening intensity

A measurement of the energy imparted to a materials surface by a stream of shot. The intensity is determined from interpretation of an Almen saturation curve. The peening intensity is the first point on a curve (not necessarily a data point) and commonly referred to as “T1.” Beyond this point, the curve or arc height of the Almen strip increases by no more than 10% when the peening time is doubled (“2T”).Plastic deformation

Deformation that remains permanent after removal of the load that caused it.Pressure pot

A closed container that provides a uniform flow of material at a consistent pressure to the blast nozzle in pneumatic blasting and shot peening.

Ricochet peening

Shot peening of a surface achieved by deflecting shot off from another surface. This occurs in applications where surfaces cannot be reached by normal line-of-sight nozzles or lances.Saturation curve

A best-fit curve generated from a set of arc height readings produced by shot peening an Almen fixture for different time intervals.Shear stress

Stresses due to forces on an object when the forces are slightly offset from one another; for example, the use of scissors in cutting a material.Shot peening

A process used to produce a compressive residual stress layer and modify mechanical properties of metals. Shot peening entails impacting a surface with shot (round metallic, glass or ceramic particles) with force sufficient to create plastic deformation.

Sieving

A process in which abrasives or shot peen media is passed through one or more screens and classified according to particle size.

Stress corrosion cracking

Failure by cracking under combined action of corrosion and a tensile stress, either external (applied) or internal (residual).Tensile stress

Forces applied to a material in opposite directions.Wet blasting or wet peening

Combining water and abrasives or ceramic beads in a blast operation for cleaning or shot peening.