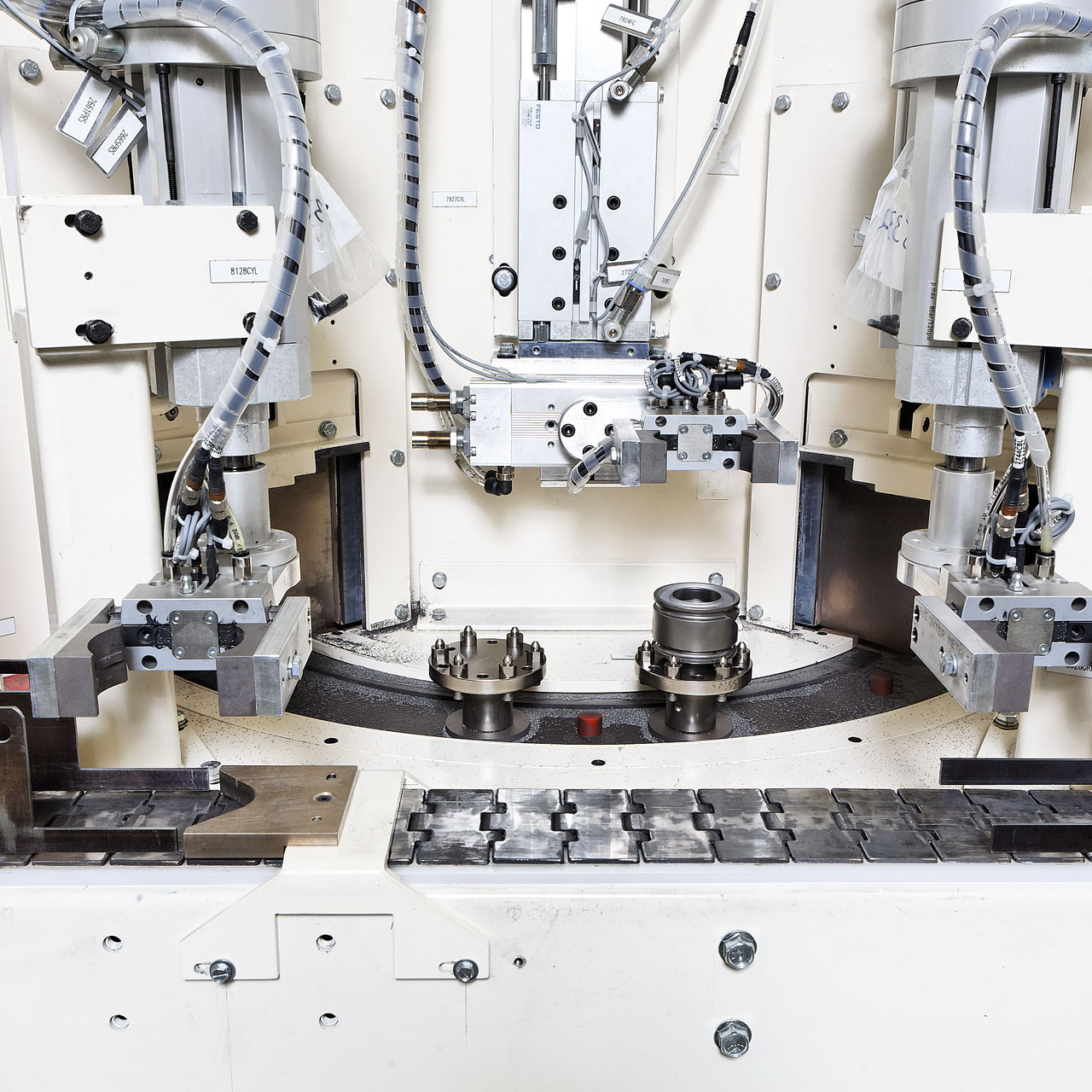

Automatic Sheet Handler and Storage Tower

Home / Custom Automation Videos / Automatic Sheet Handler and Storage Tower

Metal cutting machinery like lasers and turret punch presses can be operated “hands off” when integrated with a Progressive material storage tower and sheet handling system. This system straddles the load station and delivers sheets of raw material one at a time. A rear elevator retrieves and stores up to 8 pallets of material. The front elevator handles either the finished product pallet, or the scrap pallet. Integral suction cup system and unload “fork” system allow the metal cutting machines to run un-interrupted.

System Features and Benefits

Standard

- (4) drawer or (8) drawer storage tower

- Sheet sizes up to 2m x 4m

- 6600 lbs of material per pallet

- Suction cup loader with single sheet detection

- Fork system to unload entire table

- Safety fencing and door interlocks

Optional

- Custom design per application

- Custom controls

- Ball rollers at load station

Related Machines

Double Robotic System to Etch Aircraft Engine Components

One robot loads and rotates the part, while a second manipulates the nozzle.

Read More

High Volume Grit and Shot Blast Line

Side-by-side small rotary index machines perform two blast cleaning operations.

Read More

Automated Sheet Stacker for Laser Bed Tending

Up to eight drawers for sheet material storage and loading onto laser bed.

Read More

Gantry Area Sheet and Waste Handler for Laser Bed Tending

CNC-controlled gantries for loading full sheets and retrieving and stacking cut parts.

Read More