Suspension Plasma Spray System for Coating Semiconductor Etch Chambers

Home / Thermal Spraying Videos / Suspension Plasma Spray System for Coating Semiconductor Etch Chambers

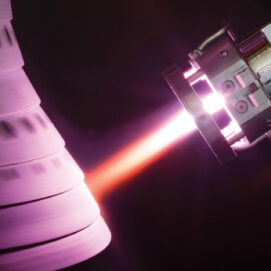

When it comes to applying a coating to the walls of a semiconductor wafer etch chamber, the right thermal spray technique makes all the difference. The goal? To produce a smooth, dense ceramic coating that will positively impact chamber lifespan and maintenance costs. In this video we compare the strengths and weaknesses of various approaches and determine the most effective thermal spray process and equipment for the job.