Heavy Equipment Overhaul Crankshaft Coating by HVOF

Home / Thermal Spraying Videos / Heavy Equipment Overhaul Crankshaft Coating by HVOF

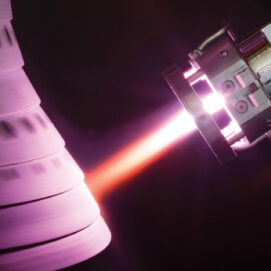

Automated cell for large, heavy, hard-to-handle components. The lathe shuttle enables the component to be loaded only once into the part manipulation lathe for the grit blast followed by HVOF surface treatment processes. The unique nozzle and torch oscillator manipulates the tip of each device to ensure constant standoff and direct impingement over the entire throw of each pin being targeted. Standoff is adjustable and automatically measured by the system prior to running an automatic cycle. System can support two lathe shuttles to allow for the loading, unloading, grit blasting or thermal spraying of two parts simultaneously.